No Products in the Cart

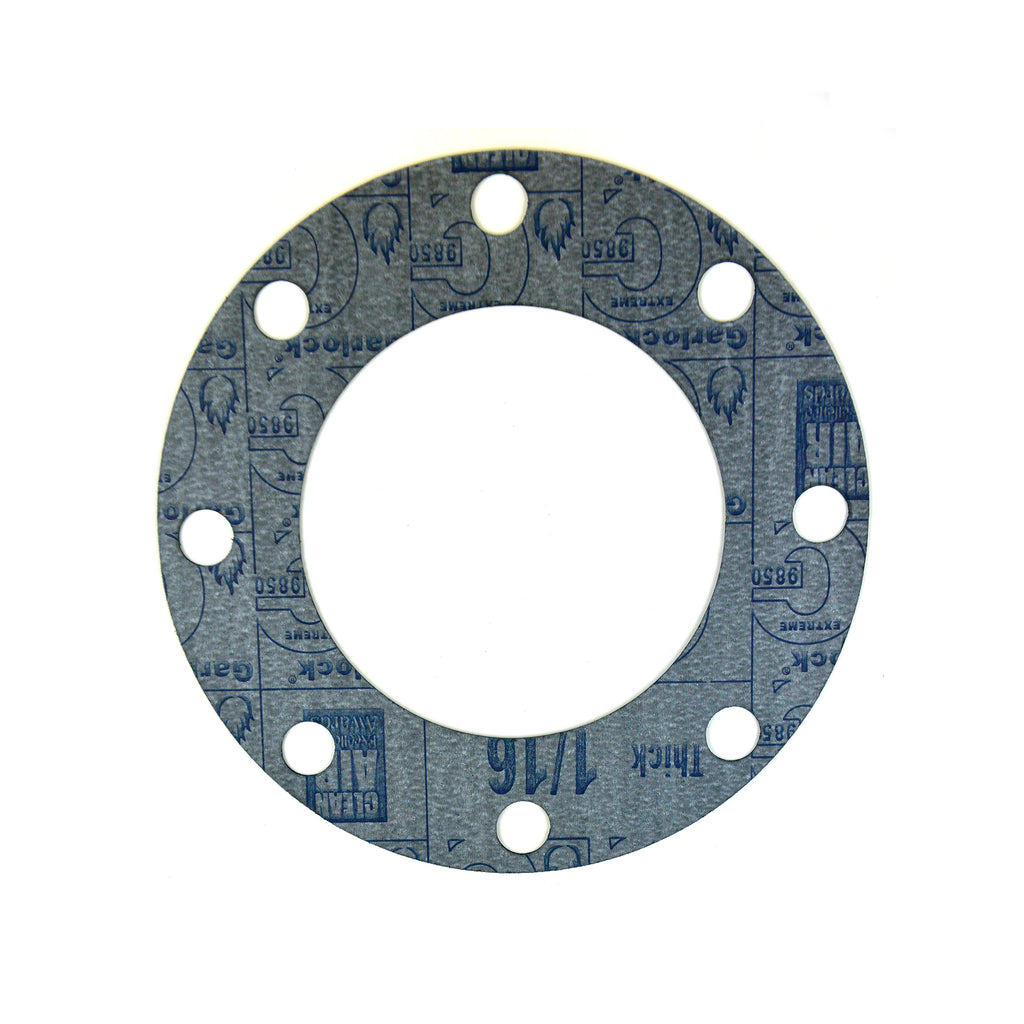

Garlock Style 9850 gasketing material composed of carbon fibers with a nitrile binder. This high temperature gasket has a long-lasting seal, which minimizes cold flow and creep relaxation problems. Garlock 9850 excels in the harshest conditions such as intense heat, high pressure, saturated steam and hot oils. This material is aboratory-tested for fire safety and produces a long-lasting seal.

The Garlock Style 9850 is ideal for applications needing standard ANSI flanged connectors as well as turbine crossover piping connectors, power generation, chemical processing, hydrocarbon processing and other industries. Additionally, Garlock 9850 is ideal for sealing involving saturated steam, oils, gasoline, water, aliphatic hydrocarbons and most refrigerants.

Garlock 9850 requires a minimum recommended assembly stress of 4,800psi with a referred assembly stress between 6,000 – 10,000psi. Gasket thickness of 1/16” strongly preferred in applications. Please retorque the bolts/studs prior to pressurizing the assembly. For saturated steam above 150 psig or superheated steam, consult the experts at Gasket Supply.

The Style 9850 gasketing material excels in the harshest conditions such as intense heat, high pressure, saturated steam and hot oils. It has been laboratory tested for fire safety and creates a long lasting seal.

*Minimum recommended assembly stress = 4,800psi. Preferred assembly stress = 6,000 – 10,000psi. Gasket thickness of 1/16” strongly preferred. Retorque the bolts/studs prior to pressurizing the assembly. For saturated steam above 150 psig or superheated steam, consult the Gasket Supply sales team.

Gasket sizes are based on ASME/ANSI Class 150lb dimensions. For Class 300lb gaskets, custom cut gaskets, or any sizing questions, please feel free to reach out to a specialist for assistance >>